The small manufacturing business sector continues to be the backbone of the global economy, with small manufacturing firms representing 98% of manufacturing firms and employing 4.8 million workers in the United States alone. As we navigate through 2025, small manufacturing businesses face unprecedented opportunities alongside unique challenges that require strategic planning, innovative solutions, and the right technology stack to thrive in an increasingly competitive marketplace.

Understanding the Small Manufacturing Business Landscape in 2025

The manufacturing industry has undergone significant transformation in recent years, with B2B buyers shifting almost entirely online in their supplier searches, making Search Engine Optimization (SEO) no longer optional but a core growth engine for small and mid-sized manufacturing companies. This digital shift represents both a challenge and an opportunity for small manufacturing businesses looking to expand their market reach and customer base.

Small manufacturing businesses typically operate with limited resources but offer significant advantages including flexibility, customization capabilities, and the ability to respond quickly to market demands. These businesses often serve niche markets where larger manufacturers cannot compete effectively, making them essential players in the supply chain ecosystem.

Key Characteristics of Successful Small Manufacturing Businesses

Modern small manufacturing businesses share several common characteristics that contribute to their success:

Agility and Flexibility: Unlike large corporations, small manufacturing businesses can pivot quickly to meet changing market demands, adopt new technologies, and implement process improvements without lengthy approval chains.

Specialized Expertise: Many small manufacturers focus on specific product categories or serve particular industry niches, allowing them to develop deep expertise and build strong customer relationships.

Customer-Centric Approach: Small manufacturing businesses often provide personalized service and custom solutions that larger competitors cannot match, creating strong customer loyalty and repeat business.

Innovation Focus: With shorter development cycles and closer customer relationships, small manufacturers can innovate rapidly and bring new products to market faster than their larger counterparts.

Essential CRM Solutions for Small Manufacturing Businesses

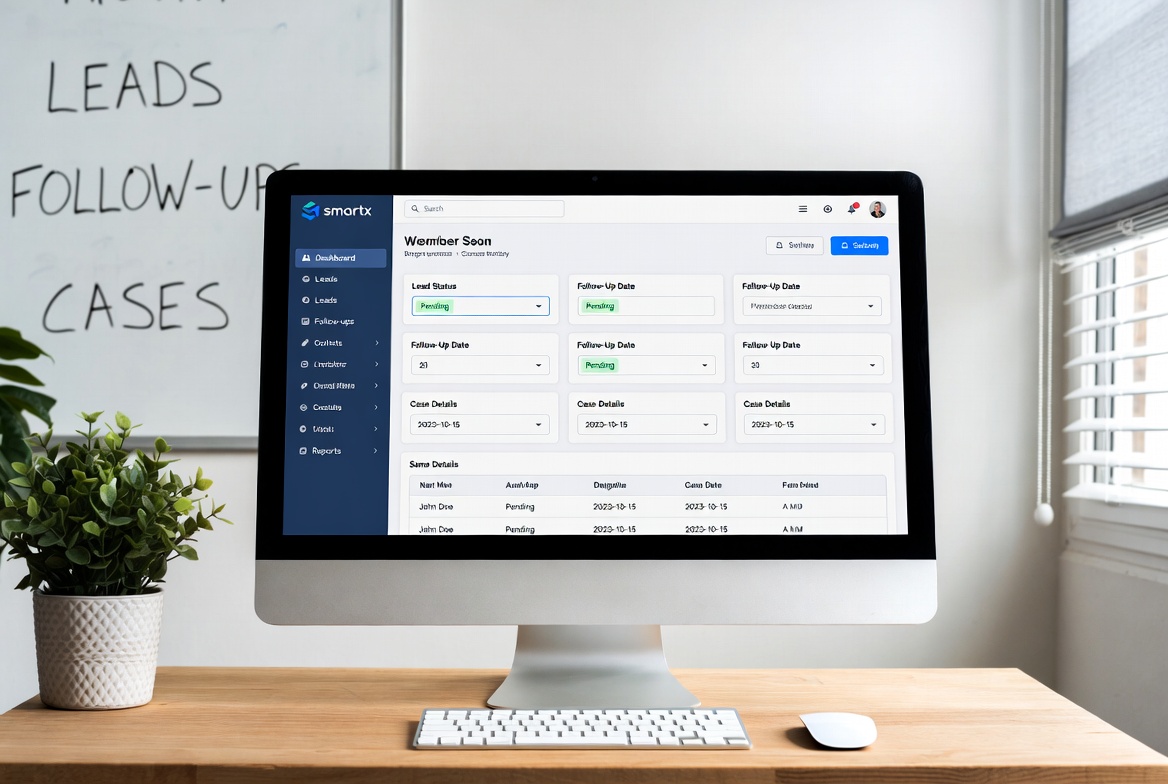

Customer Relationship Management (CRM) systems have become critical for small manufacturing businesses seeking to streamline operations and accelerate growth. CRM systems can greatly and efficiently improve the operations of any manufacturing firm by improving lead qualification, sales processes, customer service, and offering better insights into operations.

Why Manufacturing CRM is Different

Manufacturing CRMs require specialized features that go beyond traditional sales and marketing automation. Manufacturing sales processes often involve multiple steps and stakeholders, requiring CRM systems with sales pipeline management capabilities that allow businesses to visualize and manage the entire sales process, from lead generation to closing the deal.

For small manufacturing businesses, implementing the right CRM solution can transform operations by:

Streamlining Lead Management: Modern lead generation CRM systems help manufacturing businesses capture, qualify, and nurture leads more effectively, ensuring no potential customer falls through the cracks.

Improving Sales Forecasting: CRM software helps manufacturers forecast demand more accurately, enabling agile production adjustments by leveraging historical sales data and consumption patterns.

Enhancing Customer Service: With consolidated customer data, both sales and service teams can provide more personalized interactions and resolve issues faster.

Automating Routine Tasks: By automating routine tasks like updating customer records, sales teams can focus more on high-value activities like closing deals and nurturing relationships.

Key Features to Look for in Manufacturing CRM

When selecting a CRM for your small manufacturing business, consider these essential features:

Integration Capabilities: Your CRM should integrate seamlessly with existing systems including ERP, inventory management, and accounting software to create a unified business ecosystem.

Customization Options: The more you can mold your CRM software to your business, the better. Look for configurable CRM systems that allow you to personalize the user interface and create custom reports and dashboards.

Mobile Accessibility: Mobile-ready platforms let staff manage customer and sales data without being tied to a desk, essential for manufacturing environments where mobility is crucial.

Security Features: Security functions safeguard sensitive details, building trust with customers and keeping information safe, particularly important when handling proprietary manufacturing processes and customer data.

Strategic Lead Generation for Small Manufacturing Businesses

Lead generation remains the lifeblood of small manufacturing businesses, but the approaches and channels have evolved significantly. Traditional methods like trade shows and cold calling are being supplemented and sometimes replaced by digital strategies that offer better tracking, lower costs, and higher conversion rates.

Digital Lead Generation Strategies

Content Marketing and SEO: Creating valuable content that addresses customer pain points and optimizing for relevant keywords helps attract qualified leads organically. Focus on long-tail keywords like “custom manufacturing services for small businesses” or “precision parts manufacturing near me” to capture high-intent searches.

Social Media and Professional Networks: LinkedIn has become particularly valuable for B2B manufacturing companies, allowing them to showcase capabilities, share case studies, and connect directly with decision-makers.

Email Marketing Automation: Nurturing leads through automated email sequences that provide educational content, product updates, and relevant industry insights helps maintain engagement throughout longer B2B sales cycles.

Website Lead Capture: Implementing strategic lead magnets such as downloadable guides, case studies, or free consultations can significantly increase conversion rates from website visitors.

Leveraging Technology for Lead Generation

Modern manufacturing lead generation CRM systems offer sophisticated tools for capturing and nurturing leads:

Automated Lead Scoring: Systems can automatically score leads based on behavior, demographics, and engagement levels, helping sales teams prioritize their efforts.

Multi-Channel Tracking: Understanding which channels generate the highest quality leads allows for better resource allocation and marketing spend optimization.

Lead Attribution: Accurate tracking of the customer journey from first touch to final sale helps optimize marketing campaigns and improve ROI.

Operational Excellence in Small Manufacturing

Achieving operational excellence requires a combination of efficient processes, quality control measures, and continuous improvement initiatives. Small manufacturing businesses have unique advantages in implementing lean manufacturing principles due to their size and flexibility.

Implementing Lean Manufacturing Principles

Value Stream Mapping: Identify and eliminate waste in your production processes by mapping the entire value stream from raw materials to finished products.

Just-in-Time Production: Reduce inventory costs and improve cash flow by aligning production closely with customer demand.

Continuous Improvement Culture: Foster an environment where employees are encouraged to identify inefficiencies and suggest improvements.

Quality at the Source: Implement quality control measures at each stage of production rather than relying solely on final inspection.

Technology Integration for Operational Efficiency

Production Planning Software: Tools that help optimize production schedules, manage capacity, and coordinate with supply chain partners.

Inventory Management Systems: Real-time tracking of raw materials and finished goods to prevent stockouts and reduce carrying costs.

Quality Management Systems: Digital tools for tracking quality metrics, managing non-conformances, and maintaining audit trails.

Maintenance Management: Preventive maintenance scheduling and tracking to minimize equipment downtime and extend asset life.

Financial Management and Growth Strategies

Small manufacturing businesses face unique financial challenges including high capital requirements, long cash conversion cycles, and the need to maintain adequate working capital. Effective financial management is crucial for sustainable growth.

Cash Flow Optimization

Invoice Management: Implement systems to track invoices, manage payment terms, and follow up on overdue accounts to improve cash flow.

Inventory Optimization: Balance the need to maintain adequate stock levels with the cost of carrying inventory through better demand forecasting and supplier relationships.

Equipment Financing: Explore various financing options for equipment purchases including loans, leases, and equipment financing programs specifically designed for manufacturers.

Scaling Strategies for Growth

Market Expansion: Identify new geographic markets or customer segments that align with your manufacturing capabilities and expertise.

Product Line Extension: Leverage existing capabilities to develop complementary products that serve the same customer base.

Strategic Partnerships: Form alliances with complementary manufacturers or suppliers to expand capabilities without significant capital investment.

Technology Upgrades: Invest in automation and advanced manufacturing technologies to improve efficiency and capacity.

Customer Relationship Management Best Practices

Building and maintaining strong customer relationships is critical for small manufacturing businesses, especially given the typically longer sales cycles and higher transaction values in B2B manufacturing.

Understanding Customer Needs

Regular Communication: Maintain ongoing dialogue with customers to understand changing needs and anticipate future requirements.

Customer Feedback Systems: Implement formal processes for collecting and acting on customer feedback to drive continuous improvement.

Performance Metrics: Track key performance indicators such as on-time delivery, quality metrics, and customer satisfaction scores.

Building Long-Term Partnerships

Value-Added Services: Offer additional services such as design consultation, prototyping, or after-sales support to differentiate from competitors.

Collaborative Planning: Work closely with key customers on demand planning and product development to strengthen relationships.

Transparency: Provide customers with visibility into production schedules, quality processes, and any potential issues that might affect their orders.

Digital Transformation for Small Manufacturers

The digital transformation of manufacturing continues to accelerate, with over 80% of large businesses that have hourly employees expected to invest in advanced workforce management software solutions by 2025. Small manufacturers must embrace digital technologies to remain competitive.

Key Digital Technologies

Internet of Things (IoT): Connected sensors and devices provide real-time data on equipment performance, environmental conditions, and production metrics.

Artificial Intelligence and Machine Learning: AI-powered analytics can optimize production schedules, predict maintenance needs, and improve quality control.

Cloud Computing: Cloud-based systems offer scalable, cost-effective solutions for data storage, software applications, and collaboration tools.

Digital Twin Technology: Virtual representations of physical assets enable better design, testing, and optimization of manufacturing processes.

Implementation Strategies

Start Small: Begin with pilot projects that demonstrate clear ROI before scaling digital initiatives across the organization.

Employee Training: Invest in training programs to ensure employees can effectively use new technologies and systems.

Data Strategy: Develop a comprehensive data strategy that addresses collection, storage, analysis, and security requirements.

Partnership Approach: Work with technology partners who understand manufacturing requirements and can provide ongoing support.

Quality Control and Compliance

Maintaining consistent quality while meeting regulatory requirements is essential for small manufacturing businesses, particularly those serving highly regulated industries such as aerospace, medical devices, or automotive.

Quality Management Systems

ISO Standards: Consider implementing ISO 9001 or industry-specific quality standards to demonstrate commitment to quality and open doors to new customers.

Statistical Process Control: Use data-driven approaches to monitor and control manufacturing processes, identifying variations before they impact product quality.

Supplier Quality Management: Extend quality requirements to suppliers and implement systems for monitoring and improving supplier performance.

Regulatory Compliance

Stay Informed: Keep current with relevant regulations and industry standards that affect your products and processes.

Documentation Systems: Maintain comprehensive documentation of processes, procedures, and quality records to support compliance audits.

Training Programs: Ensure employees understand their roles in maintaining compliance and quality standards.

Supply Chain Management

Effective supply chain management is crucial for small manufacturing businesses, particularly in an era of global supply chain disruptions and increasing customer expectations for faster delivery times.

Supplier Relationship Management

Diversification Strategy: Maintain relationships with multiple suppliers for critical materials to reduce risk of supply disruptions.

Performance Monitoring: Track supplier performance metrics including delivery times, quality levels, and responsiveness to issues.

Collaborative Planning: Work closely with key suppliers on demand forecasting and capacity planning to ensure adequate supply.

Inventory Optimization

ABC Analysis: Categorize inventory items based on their importance and value to optimize stocking strategies and investment.

Safety Stock Calculations: Use statistical methods to determine appropriate safety stock levels that balance customer service with inventory costs.

Demand Forecasting: Implement forecasting systems that consider historical trends, seasonality, and market conditions.

Marketing and Sales Strategies

Small manufacturing businesses must develop sophisticated marketing and sales strategies to compete effectively with larger competitors while leveraging their unique advantages.

Digital Marketing Approaches

Search Engine Optimization: Optimize your website and content for manufacturing-specific keywords to attract qualified leads through organic search.

Content Marketing: Create valuable content that demonstrates expertise and helps potential customers solve problems related to manufacturing challenges.

Social Proof: Leverage customer testimonials, case studies, and success stories to build credibility with potential customers.

Sales Process Optimization

Sales Pipeline Management: Implement systematic approaches to managing prospects through the sales process, from initial contact to closed deals.

Proposal Automation: Use tools to streamline the proposal process and ensure consistent, professional presentations to prospects.

Customer Onboarding: Develop structured processes for onboarding new customers to ensure successful project launches and long-term relationships.

Future Trends and Opportunities

Looking ahead, several trends will continue to shape the small manufacturing business landscape:

Sustainability and Green Manufacturing

Environmental consciousness is driving demand for sustainable manufacturing practices, creating opportunities for small manufacturers who can demonstrate environmental responsibility while maintaining competitive pricing.

Customization and Mass Personalization

Advances in flexible manufacturing technologies enable small manufacturers to offer increasing levels of customization without sacrificing efficiency.

Nearshoring and Supply Chain Resilience

Global supply chain disruptions are driving companies to seek suppliers closer to home, creating opportunities for domestic small manufacturers.

Advanced Materials and Technologies

Emerging materials and manufacturing technologies such as 3D printing and advanced composites create new market opportunities for innovative small manufacturers.

Conclusion

The small manufacturing business sector continues to evolve rapidly, driven by technological advances, changing customer expectations, and global economic forces. Success in this environment requires a strategic approach that combines operational excellence with customer-focused service delivery, enabled by the right technology infrastructure.

By implementing comprehensive CRM systems for small businesses, optimizing lead generation processes, and embracing digital transformation, small manufacturing businesses can not only survive but thrive in the competitive landscape of 2025 and beyond.

The key is to start with a clear understanding of your unique value proposition, invest in the right technologies and processes to support growth, and maintain an unwavering focus on customer satisfaction and operational excellence. With the right strategies and tools, small manufacturing businesses can achieve sustainable growth while building lasting competitive advantages in their chosen markets.

Whether you’re just starting your manufacturing business or looking to scale existing operations, the strategies and insights outlined in this guide provide a roadmap for success in the dynamic world of modern manufacturing. By staying focused on customer needs, embracing technology, and maintaining operational excellence, your small manufacturing business can achieve remarkable growth and success in 2025 and beyond.

Leave a comment: