The manufacturing industry is evolving rapidly, and small manufacturing businesses face unique challenges that require smart solutions. From managing supplier relationships to tracking production schedules and coordinating with distributors, small manufacturers juggle countless moving parts daily. This is where a manufacturing CRM for small businesses becomes not just helpful, but essential for survival and growth.

In this comprehensive guide, we’ll explore how the right CRM software can transform your small manufacturing business, streamline operations, and position you for sustainable growth in 2025 and beyond.

What is Manufacturing CRM and Why Do Small Businesses Need It?

A manufacturing CRM (Customer Relationship Management) system is specialized software designed to help manufacturing companies manage customer interactions, sales processes, production workflows, and supplier relationships—all from a centralized platform.

Unlike generic CRM solutions, a manufacturing-focused CRM understands the complexities of the production environment. It bridges the gap between your sales team, production floor, quality control, and distribution channels.

The Unique Challenges Small Manufacturers Face

Small manufacturing businesses operate in a competitive landscape with razor-thin margins. Here are the critical challenges they face daily:

Complex Sales Cycles: Manufacturing sales often involve multiple stakeholders, custom quotes, technical specifications, and lengthy approval processes. Without proper tracking, opportunities slip through the cracks.

Inventory and Production Coordination: Balancing raw material inventory, production capacity, and delivery commitments requires precise coordination. A miscommunication can lead to stockouts, production delays, or excess inventory.

Supplier Relationship Management: Manufacturing relies on timely deliveries from multiple suppliers. Managing these relationships, tracking purchase orders, and monitoring supplier performance is crucial.

Quality Control and Compliance: Small manufacturers must maintain quality standards and often comply with industry regulations. Documentation and traceability become critical.

Limited Resources: Unlike large manufacturers, small businesses operate with lean teams. Every team member wears multiple hats, making efficiency paramount.

A purpose-built CRM software for small businesses addresses these challenges head-on, providing tools that automate routine tasks and centralize critical information.

Key Benefits of Manufacturing CRM for Small Businesses

Implementing a manufacturing CRM delivers transformative benefits that directly impact your bottom line:

1. Streamlined Lead Management and Sales Process

Manufacturing sales cycles are notoriously complex, often spanning weeks or months. A robust CRM helps you track every lead from initial inquiry through quote generation, negotiations, and final order.

With lead management capabilities, you can prioritize high-value opportunities, assign leads to the right sales representatives, and ensure no potential customer falls through the cracks. The system provides visibility into where each opportunity stands in your pipeline, helping you forecast revenue more accurately.

2. Enhanced Customer Communication and Relationship Building

In manufacturing, relationships matter immensely. Your CRM becomes the single source of truth for all customer interactions—emails, phone calls, meetings, and technical discussions. This historical context ensures that anyone on your team can pick up a conversation without missing a beat.

SmartX CRM’s communication tools help you maintain consistent touchpoints with customers, sending automated follow-ups, production updates, and delivery notifications that keep clients informed and satisfied.

3. Improved Quote Management and Pricing Accuracy

Creating accurate quotes quickly is crucial in manufacturing. A manufacturing CRM stores product specifications, pricing structures, and historical quote data, enabling your sales team to generate professional, accurate quotes in minutes rather than hours.

The system can track quote versions, approval workflows, and conversion rates, helping you understand which products, pricing strategies, and terms win more business.

4. Better Inventory and Production Visibility

While a CRM isn’t a full ERP system, modern manufacturing CRMs integrate with production systems to provide sales teams with real-time inventory levels and production capacity. This visibility prevents over-promising and enables realistic delivery commitments.

Your sales team can check material availability and production schedules before committing to delivery dates, reducing the risk of disappointing customers with delays.

5. Automated Workflows and Task Management

Manufacturing involves numerous repetitive tasks—sending order confirmations, requesting production updates, following up on deliveries, and collecting payments. SmartX CRM’s automation suite eliminates manual work by automating these routine processes.

You can set tasks and reminders that ensure nothing falls through the cracks, while your team focuses on high-value activities that drive growth.

6. Data-Driven Decision Making

A manufacturing CRM captures valuable data about customer behavior, sales performance, product popularity, and market trends. Built-in analytics transform this raw data into actionable insights.

You can identify your most profitable customer segments, track which products have the highest margins, understand seasonal demand patterns, and make informed decisions about where to focus your resources.

7. Scalability for Growing Manufacturers

As your small manufacturing business grows, your CRM grows with you. You can add users, expand functionality, and integrate additional tools without disrupting operations. This scalability ensures your technology investment continues delivering value as your business evolves.

Essential Features to Look for in Manufacturing CRM Software

Not all CRMs are created equal, especially when it comes to manufacturing. Here are the must-have features for small manufacturers:

Contact and Account Management

Your CRM should maintain comprehensive profiles for customers, suppliers, distributors, and partners. This includes contact information, communication history, purchase history, payment terms, and custom fields specific to manufacturing relationships.

Advanced Lead Tracking and Pipeline Management

Look for visual pipeline management that shows exactly where each opportunity stands. The ability to customize sales stages to match your manufacturing sales process is essential. Lead generation and management capabilities should be robust and tailored to B2B manufacturing environments.

Quote and Order Management

The system should streamline quote creation with templates, product catalogs, and pricing rules. It should track quote history, manage revisions, and seamlessly convert accepted quotes into orders.

Integration Capabilities

Your CRM must integrate with other essential business tools—accounting software, ERP systems, email platforms, and communication tools. This connectivity eliminates data silos and ensures information flows smoothly across your organization.

Mobile Access

Manufacturing doesn’t happen only at a desk. Your sales team, production managers, and even executives need mobile access to customer information, production status, and critical updates while on the factory floor or visiting clients.

Reporting and Analytics

Comprehensive reporting capabilities help you track key performance indicators (KPIs) like sales velocity, quote-to-order conversion rates, customer acquisition costs, and customer lifetime value. Customizable dashboards provide at-a-glance insights into business health.

Task Automation and Workflow Management

Automated follow-ups, task assignments, and approval workflows reduce manual work and ensure consistency. The system should support custom workflows that match your unique manufacturing processes.

Document Management

Manufacturing involves extensive documentation—technical specifications, quality certificates, compliance documents, and contracts. Your CRM should centralize these documents, making them easily accessible and properly organized.

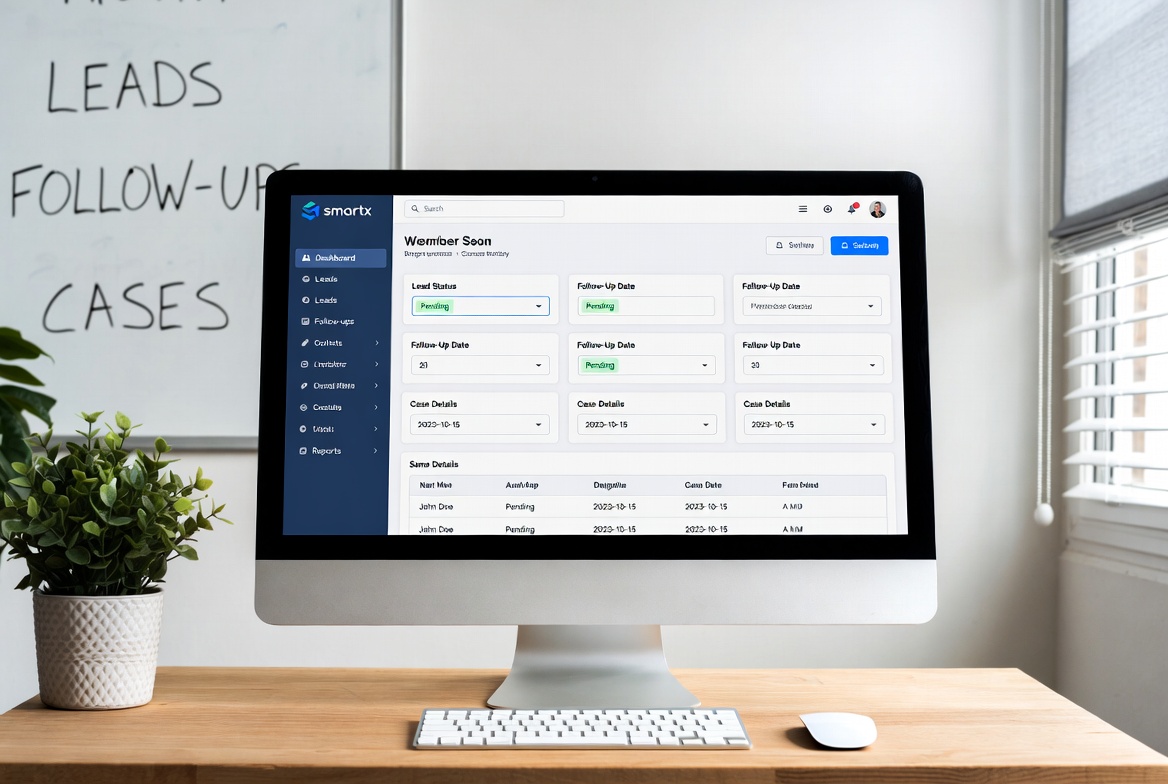

How SmartX CRM Transforms Manufacturing Operations

SmartX CRM is purpose-built to address the unique needs of small manufacturing businesses. Here’s how it delivers value:

Unified Platform for All Customer Interactions

SmartX CRM centralizes every customer touchpoint, creating a complete history of interactions. Whether a customer calls about a technical specification, emails about delivery timing, or visits your facility, everything is documented in one place.

This unified view empowers your team to deliver personalized, informed service that builds stronger customer relationships and increases repeat business.

Intelligent Lead Routing and Management

When a potential customer inquires about your manufacturing capabilities, SmartX CRM automatically captures and routes the lead to the appropriate sales representative based on territory, product expertise, or workload. This intelligent lead management ensures prompt response times and higher conversion rates.

Seamless Quote-to-Cash Process

From initial inquiry through quote creation, order processing, production tracking, delivery confirmation, and invoicing, SmartX CRM manages the entire quote-to-cash cycle. This end-to-end visibility eliminates bottlenecks and accelerates revenue realization.

Real-Time Collaboration Tools

Manufacturing requires coordination between sales, production, quality control, and logistics teams. SmartX CRM facilitates this collaboration with shared notes, task assignments, and internal messaging that keeps everyone aligned.

Powerful Automation Engine

SmartX CRM’s automation capabilities transform how your manufacturing business operates. Automatically send order confirmations, production status updates, and delivery notifications. Set up workflows that trigger actions based on specific events—like alerting production when a high-priority order is received.

Custom Manufacturing Workflows

Every manufacturing business is unique. SmartX CRM allows you to create custom fields, workflows, and processes that match your specific operations. Whether you’re doing made-to-order manufacturing, batch production, or continuous manufacturing, the system adapts to your needs.

Integration with Manufacturing Tools

SmartX CRM integrates with popular manufacturing and business tools, creating a connected ecosystem. Sync with your accounting software for seamless invoicing, connect to your ERP for inventory visibility, and integrate with communication platforms for unified messaging.

Manufacturing CRM vs Excel: Why You Need to Upgrade

Many small manufacturers still rely on spreadsheets to manage customer relationships, quotes, and orders. While Excel is versatile, it’s fundamentally inadequate for modern manufacturing operations.

Comparing CRM vs Excel reveals critical limitations of spreadsheets:

No Real-Time Collaboration: Multiple users editing Excel files leads to version conflicts, lost data, and confusion. A CRM provides real-time updates visible to all team members simultaneously.

Limited Automation: Excel requires manual data entry for virtually everything. A CRM automates routine tasks, saving hours of work weekly.

Poor Mobile Experience: Excel spreadsheets are difficult to use on mobile devices. Manufacturing CRMs offer native mobile apps designed for on-the-go access.

Lack of Integration: Excel exists in isolation. CRMs integrate with email, accounting, communication tools, and other business systems.

Security Risks: Excel files can be easily lost, corrupted, or accessed by unauthorized users. CRMs offer robust security, backup, and access controls.

Scalability Issues: As your data grows, Excel becomes slower and more unwieldy. CRMs are built to handle growth seamlessly.

The transition from Excel to a manufacturing CRM represents a fundamental shift from reactive data management to proactive business growth.

Implementing Manufacturing CRM: Best Practices for Success

Implementing a CRM system is a strategic initiative that requires planning and commitment. Here’s how to ensure success:

1. Define Clear Objectives

Before selecting a CRM, identify specific problems you want to solve. Are you losing track of leads? Struggling with quote accuracy? Missing follow-up opportunities? Clear objectives guide your CRM selection and implementation.

2. Get Leadership Buy-In

CRM success requires support from company leadership. Executives must champion the initiative, allocate necessary resources, and set expectations for adoption.

3. Involve End Users Early

The people who will use the CRM daily—sales representatives, customer service staff, production coordinators—should participate in the selection process. Their input ensures the chosen system meets real-world needs and increases adoption rates.

4. Start with Core Features

Resist the temptation to implement every feature immediately. Begin with core functionality like contact management, lead tracking, and basic automation. As your team becomes comfortable, gradually introduce advanced features.

5. Migrate Data Carefully

Clean your existing customer data before importing it into the new CRM. Remove duplicates, standardize formats, and verify accuracy. Poor data quality undermines CRM effectiveness from day one.

6. Provide Comprehensive Training

Invest in thorough training for all users. SmartX CRM offers onboarding support, training materials, and ongoing assistance to ensure your team masters the system quickly.

7. Customize Thoughtfully

While customization is powerful, over-customization can complicate the system. Focus on customizations that directly support your manufacturing processes and provide clear value.

8. Monitor Adoption and Usage

Track how your team uses the CRM. Are they logging activities consistently? Creating opportunities? Following workflows? Low adoption indicates training gaps or process issues that need attention.

9. Iterate and Improve

CRM implementation isn’t a one-time event. Continuously gather feedback, identify improvement opportunities, and refine your processes. The most successful manufacturers treat their CRM as an evolving tool that grows with the business.

Manufacturing CRM Use Cases: Real-World Applications

Let’s explore specific scenarios where manufacturing CRM drives tangible results:

Custom Manufacturer Managing Complex Quotes

A small custom parts manufacturer receives dozens of quote requests monthly, each requiring unique specifications and pricing. With SmartX CRM, they create quote templates with configurable options. When a request arrives, the sales team generates an accurate quote in minutes, tracks it through the approval process, and automatically follows up if the customer hasn’t responded. Quote-to-order conversion rates increased by 35% after implementation.

Job Shop Balancing Multiple Customer Orders

A job shop manufacturing components for various industries struggles to keep customers informed about production status. By implementing SmartX CRM integrated with their production scheduling system, they automatically send status updates at key milestones—order received, production started, quality inspection complete, and shipped. Customer satisfaction scores improved significantly as clients gained visibility into their orders.

Distributor Coordinating Between Manufacturers and Retailers

A small distributor connecting manufacturers with retailers uses SmartX CRM to manage relationships on both sides. They track product availability from manufacturers, match it with retailer demand, and coordinate logistics. The CRM’s pipeline management shows exactly where each transaction stands, reducing fulfillment time by 40%.

Contract Manufacturer Managing Recurring Orders

A contract manufacturer producing components for several large clients has recurring orders with varying schedules and specifications. SmartX CRM tracks each client’s order history, preferences, and special requirements. Automated reminders prompt the sales team to reach out before recurring order dates, ensuring seamless continuity and reducing last-minute rush orders.

The ROI of Manufacturing CRM for Small Businesses

Investing in CRM software requires budget allocation, and small manufacturers rightfully want to understand the return on investment. Here’s how manufacturing CRM delivers measurable ROI:

Increased Sales Revenue

Better lead management, faster quote generation, and consistent follow-ups directly increase closed deals. Most small manufacturers see a 20-30% increase in sales within the first year of CRM implementation.

Improved Operational Efficiency

Automation eliminates hours of manual work weekly. Tasks that previously took 30 minutes now take 5 minutes. Across your organization, these efficiency gains add up to significant cost savings.

Reduced Customer Churn

Better communication, proactive service, and organized customer management improve retention. Acquiring new customers costs 5-7 times more than retaining existing ones, making churn reduction extremely valuable.

Higher Win Rates on Quotes

When your sales team accesses complete customer history and generates accurate quotes quickly, win rates improve. Many manufacturers report 15-25% higher quote conversion after implementing CRM.

Better Resource Allocation

Analytics reveal which customers, products, and markets generate the most profit. This insight helps you focus resources where they deliver the highest returns, improving overall profitability.

Faster Sales Cycles

Streamlined processes and better coordination reduce the time from initial inquiry to closed order. Faster sales cycles mean quicker revenue realization and improved cash flow.

Common Mistakes to Avoid When Choosing Manufacturing CRM

Small manufacturers sometimes make costly mistakes when selecting and implementing CRM systems. Avoid these pitfalls:

Choosing Based Solely on Price: The cheapest CRM often lacks essential features or scales poorly. Focus on value and total cost of ownership rather than initial price.

Ignoring Integration Requirements: A CRM that doesn’t integrate with your existing tools creates data silos and reduces efficiency. Prioritize integration capabilities.

Over-Complicating Implementation: Starting with overly complex configurations frustrates users and delays adoption. Begin simple and add complexity gradually.

Neglecting Mobile Capabilities: Manufacturing happens beyond the desk. A CRM without robust mobile functionality limits its utility.

Failing to Plan for Growth: Choose a CRM that scales with your business. Outgrowing your CRM and migrating to a new system is expensive and disruptive.

Insufficient Training Investment: A powerful CRM is worthless if your team doesn’t know how to use it. Allocate adequate time and resources for training.

Not Customizing for Manufacturing: Generic business processes don’t match manufacturing workflows. Customize your CRM to reflect how your manufacturing business actually operates.

Future Trends in Manufacturing CRM Technology

Manufacturing CRM continues evolving with emerging technologies that promise even greater capabilities:

Artificial Intelligence and Predictive Analytics

AI-powered CRMs analyze historical data to predict customer behavior, forecast demand, and identify at-risk accounts. Predictive lead scoring helps sales teams prioritize opportunities most likely to close.

IoT Integration

As manufacturers adopt IoT sensors and connected equipment, CRMs will integrate this data to provide unprecedented visibility into production status, equipment performance, and delivery tracking.

Advanced Automation

Future CRMs will offer increasingly sophisticated automation, handling complex multi-step workflows with minimal human intervention. This evolution will free manufacturing teams to focus on strategic initiatives.

Enhanced Mobile Capabilities

Mobile CRM functionality will continue improving, with augmented reality features that help sales teams visualize products in customer environments and voice-activated interfaces for hands-free operation on the factory floor.

Blockchain for Supply Chain Transparency

Blockchain integration will enable tamper-proof tracking of materials, components, and finished products throughout the supply chain, enhancing quality control and compliance documentation.

Why SmartX CRM is the Smart Choice for Small Manufacturers

Choosing the right manufacturing CRM partner is as important as the technology itself. Here’s why small manufacturers trust SmartX CRM:

Purpose-Built for Small Businesses: Unlike enterprise CRMs that overwhelm small teams with complexity, SmartX CRM delivers powerful capabilities in an intuitive, accessible platform designed for businesses like yours.

Affordable and Transparent Pricing: SmartX CRM offers straightforward pricing without hidden fees, making it accessible for small manufacturers with limited budgets.

Quick Implementation: Get up and running in days, not months. SmartX CRM’s streamlined onboarding process minimizes disruption to your operations.

Exceptional Support: When you need help, our support team responds quickly with knowledgeable assistance. We’re invested in your success.

Continuous Innovation: SmartX CRM regularly releases new features and improvements based on customer feedback, ensuring the platform evolves with your needs.

Proven Track Record: Small manufacturers across diverse industries trust SmartX CRM to manage their customer relationships and drive growth.

Taking the Next Step: Transforming Your Manufacturing Business

The manufacturing landscape is increasingly competitive, and small businesses need every advantage to thrive. A manufacturing CRM isn’t just software—it’s a strategic asset that transforms how you acquire customers, manage relationships, and grow your business.

From digital transformation to improved cold calling effectiveness, SmartX CRM provides the tools and insights you need to compete with larger manufacturers while maintaining the agility and customer focus that makes small businesses special.

The journey from scattered spreadsheets and disconnected systems to a unified, automated, data-driven operation begins with a single decision. Small manufacturers who embrace CRM technology position themselves for sustainable growth, improved profitability, and long-term success.

Understanding how SmartX CRM powers every stage of the customer journey reveals the comprehensive value of modern CRM technology. From the moment a lead enters your system through years of repeat business, SmartX CRM supports and enhances every interaction.

Conclusion: Manufacturing CRM as a Growth Catalyst

Manufacturing CRM for small businesses represents more than operational improvement—it’s a catalyst for transformation. By centralizing customer information, automating routine tasks, providing actionable insights, and facilitating better communication, the right CRM system multiplies your team’s effectiveness.

Small manufacturers face unique challenges that require specialized solutions. SmartX CRM understands these challenges and delivers purpose-built capabilities that address them directly. Whether you’re managing complex B2B relationships, coordinating production schedules, tracking supplier performance, or expanding into new markets, SmartX CRM provides the foundation for sustainable growth.

The question isn’t whether your small manufacturing business needs a CRM—it’s how much longer you can afford to operate without one. Every day without proper customer relationship management represents lost opportunities, inefficient processes, and unrealized potential.

Explore how SmartX CRM empowers businesses with smarter customer relationship management, and discover why thousands of small manufacturers trust our platform to drive their growth.

Start your transformation today. Your competitors already have.

Ready to transform your manufacturing business? Discover how SmartX CRM can streamline your operations, increase sales, and position you for growth in 2025 and beyond. Contact us for a personalized demonstration and see the difference the right CRM makes.ImproveExplain

Leave a comment: